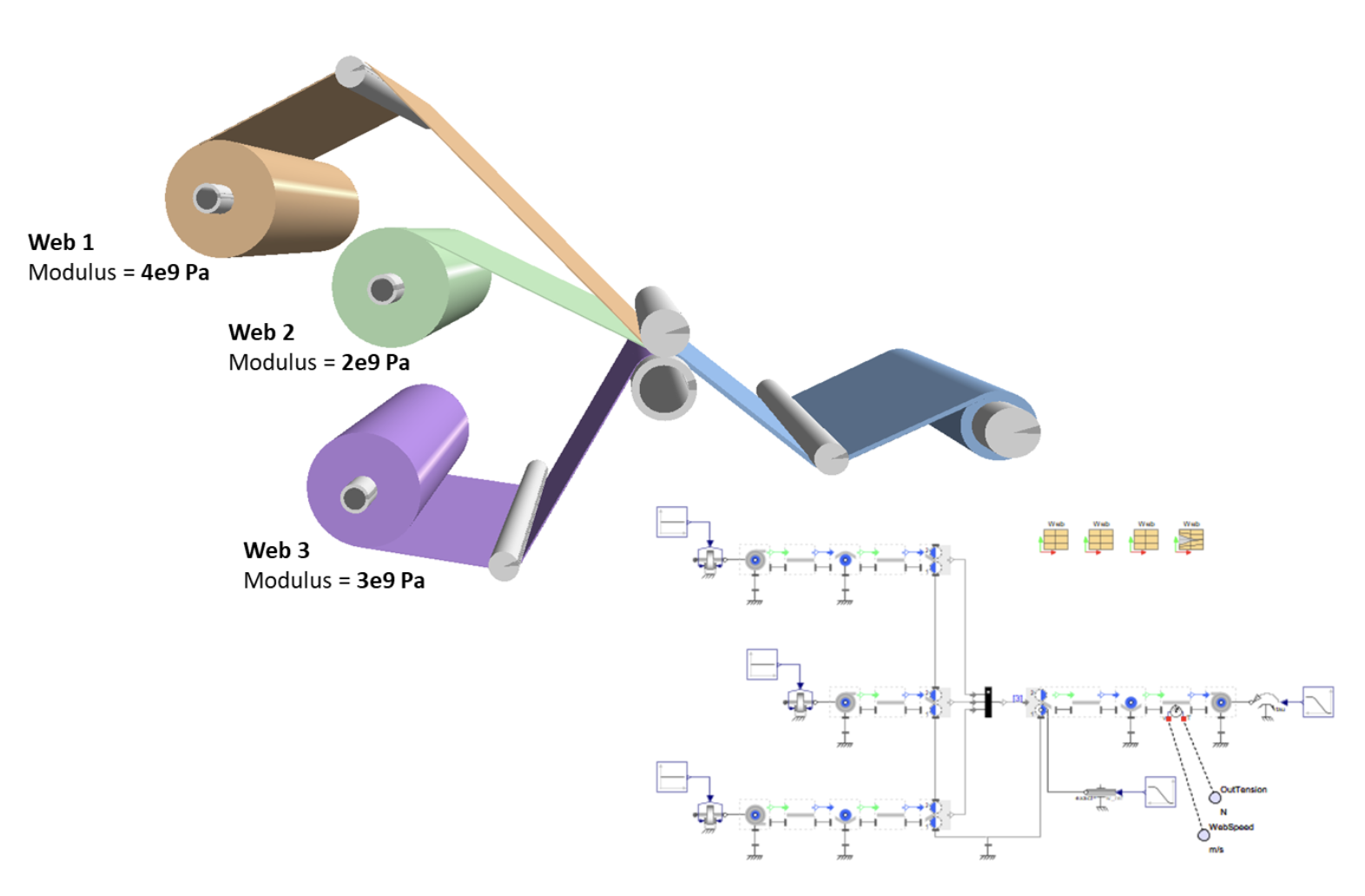

MapleSim for Web Converting Systems

Curl is a common defect in laminated webs, often caused by multiple interacting factors. One of the most critical contributors is strain mismatch between the incoming layers. When webs enter the nip under different conditions, they are forced to align to a common length during lamination. This creates uneven elastic stresses, which, once the laminate exits the rollers, can lead to out-of-plane deformation commonly known as curl. While other factors can influence curling, minimizing strain mismatch is essential for achieving a stable, flat laminate.

MapleSim’s web handling simulation tool provides a structured way to address these challenges by enabling engineers to: