User Case Study:

Improving the Line Performance of Roll-to-roll Systems using MapleSim

Highlights:

A market-leading supplier of converting and web handling machines was seeking ways to improve the throughput of their paper and plastic film converting systems while reducing quality issues arising from web tension fluctuations.

Challenges:

Quality concerns had limited the maximum web speed

The company’s machine design team had experienced unwanted web slippage at certain points on the line. The web slippage could only be remedied by reducing the overall web line speed, since steps to measure the variations in tension along the paper or plastic film would require the installation of additional load cell hardware, and even then, the team could only determine discrete information at specific roller locations.

As an alternative, the team turned to simulation, and chose to work with Maplesoft to produce a virtual model of their system that would allow them to represent the web tension across the different spans and see the effects of changing their control strategy, prior to adding any new hardware. The virtual model was created using MapleSim, an advanced modeling and simulation tool that helps reduce development time, lower costs, and diagnose real-world performance issues.

Recommended Solution:

The company had not previously used simulation in their machine design processes, but they appreciated Maplesoft’s experience with machine modeling as well as MapleSim’s overall value proposition, that of improved machine performance through virtual modeling and simulation, before resorting to expensive physical hardware changes.

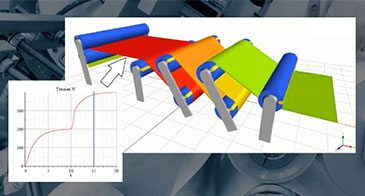

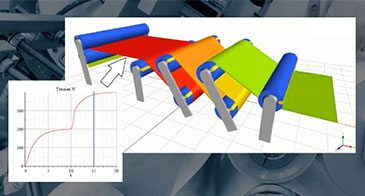

Maplesoft worked with the machine design team to create a digital model of their roll-to-roll system using pre-built components from MapleSim’s specialized Web Handling Library. The variations in paper and plastic roll size, thickness and coefficient of friction became parameters that could be adjusted quickly and simply to cover a variety of use-cases.

The company was able to tune the model using recent production data, establishing a reliable method of predicting the tension across particular converting systems. The team then analyzed the model to identify ways to minimize unwanted slippage and use control strategies to manage the tension throughout the line. These strategies were tested against the virtual model (run against an emulated PLC) prior to applying them to the production system.

Results:

The machine design team was able to develop the virtual model, create a reliable method of predicting tension across spans, and implement improvements in web tension management. By reducing tension fluctuations, the web handling machine throughput could be safely increased by as much as 8% without requiring expensive changes in hardware.

Further machine optimization produced a more consistent web quality when handling different materials, resulting in less wastage during loading and when halting the converting process.

Contact Maplesoft to request a demo and discuss how MapleSim can be used to improve your web handling system.

Products

Industry/Application Area